Metal Panel you can achieve any design for your projects. With all our products you will reduce construction time and employ the necessary product for any construction project. With products Metal Panel will have several big energy savings thanks to the excellent insulating performance temperature and sound of our panels, Polycarbonates and to allow passage of natural light.

Materials and wall coverings Metal Panel function not only to improve the appearance of the buildings but also durability, at the same time saving them money on energy and maintenance costs. With roofing materials Metal Panel, customers can be sure that your roof is resistant to the weather and has the backing of Metal Panel ensuring product quality, Besides being a cheaper product as Metal Panel has specialized machinery to manufacture products.

We represent MASTERS OF THE BEST BRANDS

[heel]How can we solve their problems?

Metal Panel we are committed to always offer the best products and the best service and delivery times, all at the best price because we have specialized infrastructure for manufacturing materials. With our products you can carry out all types of projects with the assurance that their needs will be met, because we offer customized technical advice, such as the design of the project, As to the business advice, from blueprint to completion of the same, us will have a wide range of products from panels for walls or ceilings, up profiles, Heat- or acrylic.

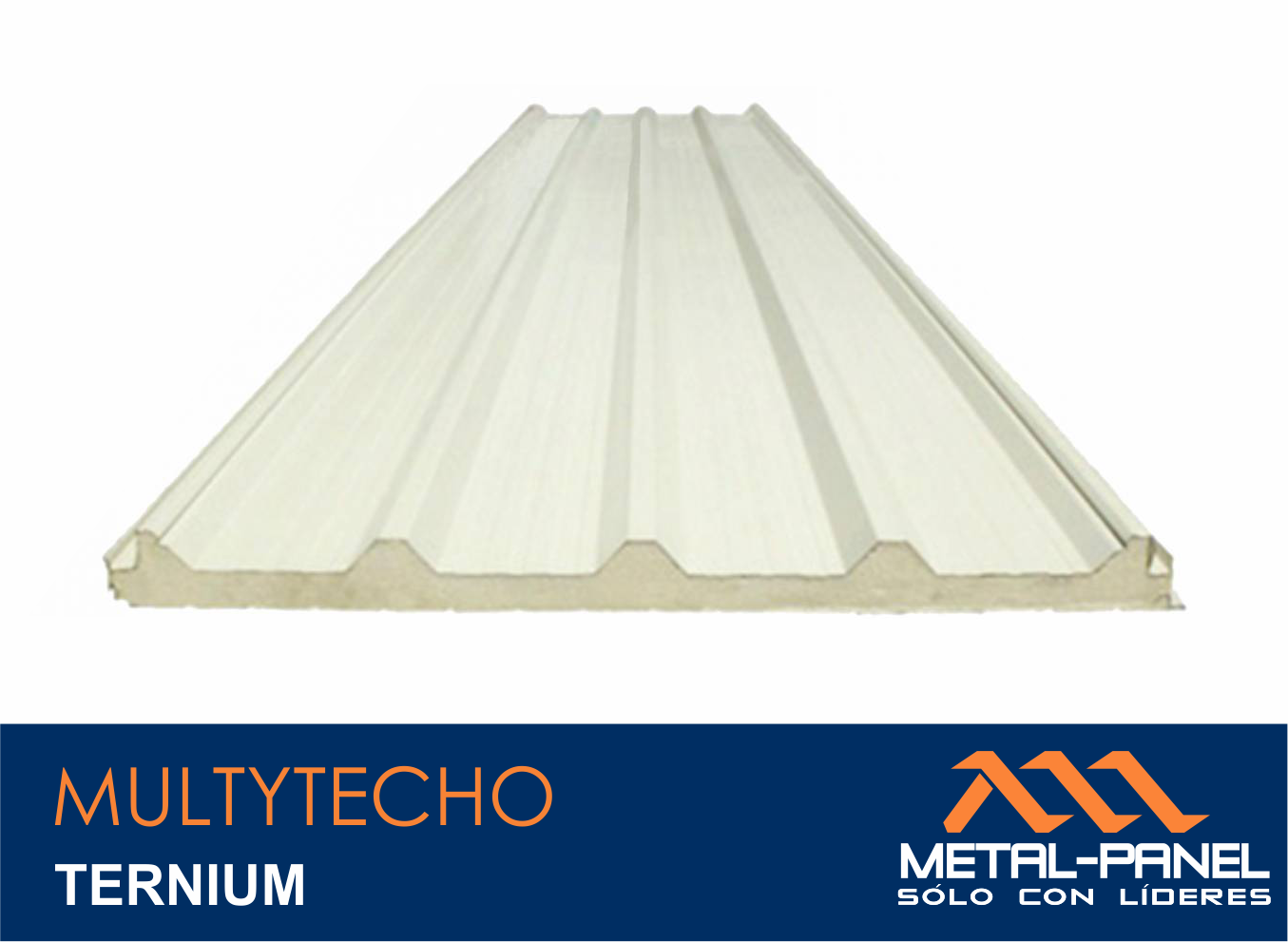

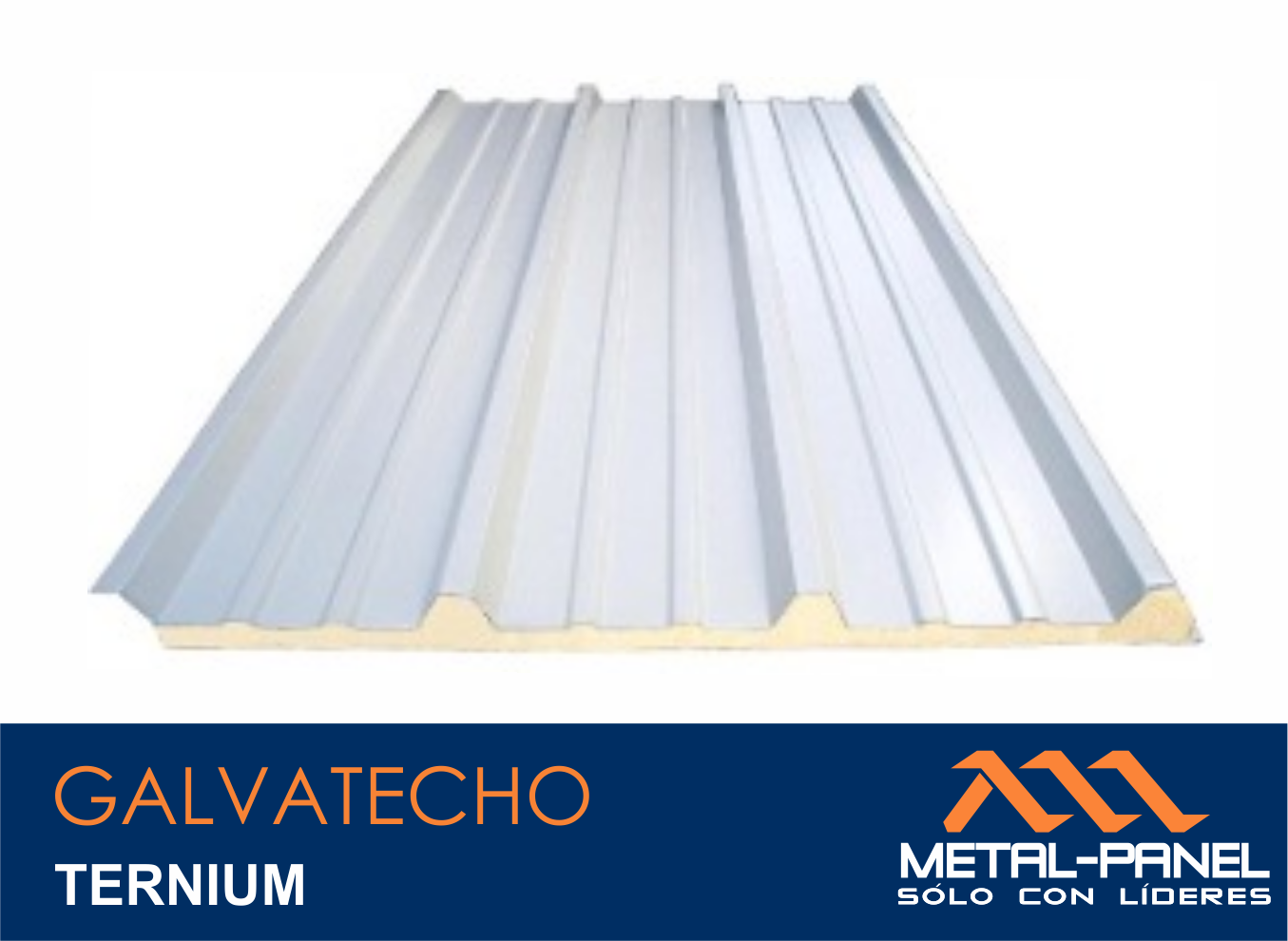

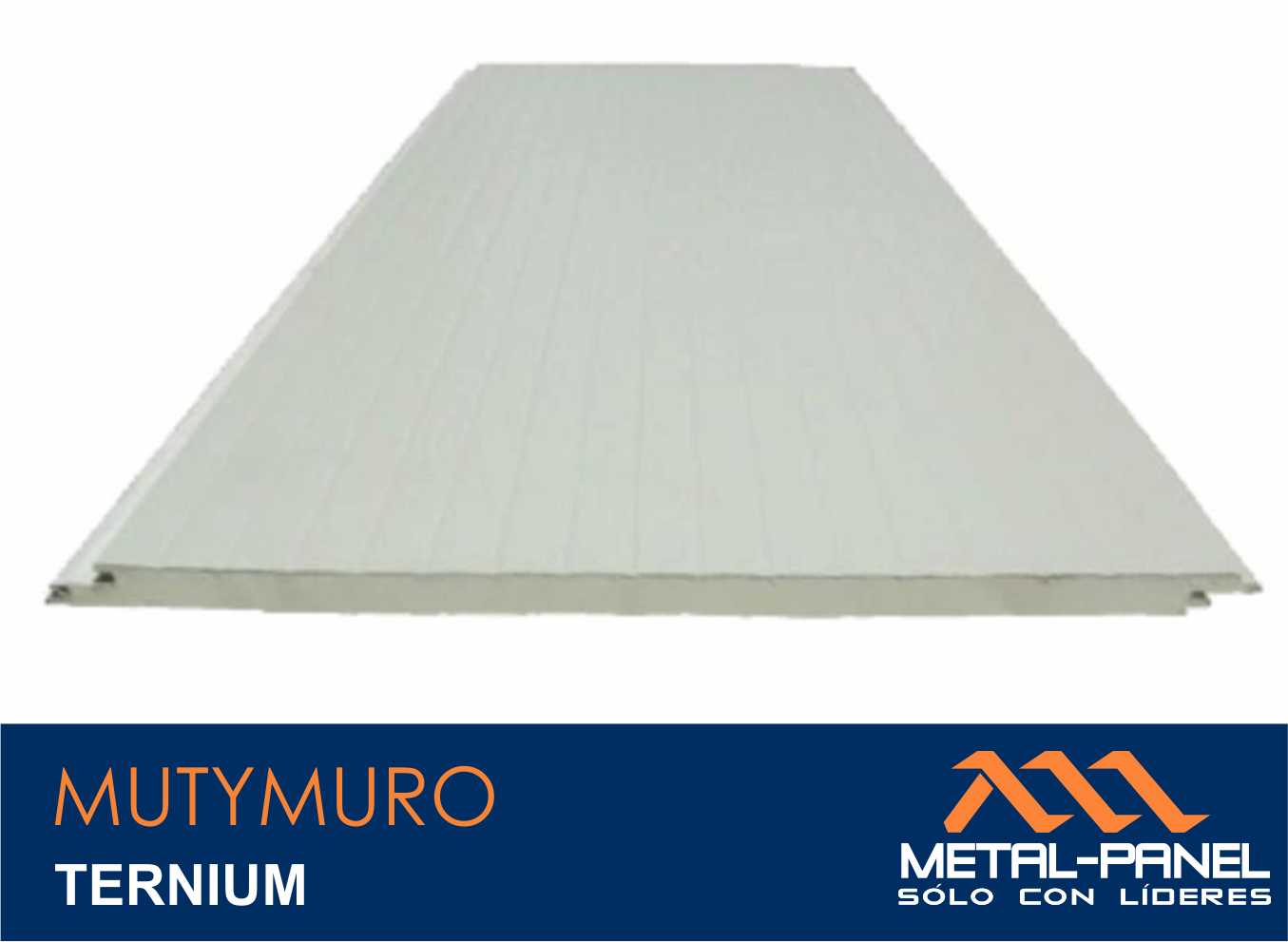

insulated panels

What is it?

Isolated Panel is an ideal versatile construction system for buildings that require quick installation, cleaning, esthetic, quality, energy saving and durability.

This system is composed by coatings (metal, plastics and other) with corrosion resistant coatings and excellent appearance, with a foam core rigid polyurethane second generation (ecological). An ideal combination of mechanical and physical properties.

Advantages and benefits

- concealed fixing and exposed

- ecological gas r-22ligero, quick and easy installation

- High structural strength

- Large capacity drain

- Saving the 30% in energy costs and air conditioning equipment

- Adaptable to other building systems

- High seismic resistance

- -Auto resistant to the fire extinguishing-

- male-female exclusive union

- clean works (no debris cause)

- Low cost savings in foundation and structure

- Technical advice on design and construction

- Written guarantee

- It has international approvals

- Material 100% finished

- Low maintenance

- Detachable and turn it back arm

Why install insulated panel?

- Lower costs, saving installation time, light structures, lower energy consumption.

- technical developments, architectural requirements.

- Detection advantages of the construction system.

- Product diversity panels with specific applications.

- Chillers

- thermal resistance (factor R), proof joints water vapor diffusion, cost reduction cold

- Quality assurance chilled products, because more uniform indoor climate.

Why install panel instead of conventional materials like concrete or block?

This type of construction has acquired over time, a number of advantages over traditional construction that prioritizes and improves the construction process of the building, and conflict factors traditionally acquired in a work:

- Conditions of greater control over the installation due to the ease of installation compared to the traditional system.

- less environmental impact, since the products have some degree of reuse and lower levels of waste.

- times more tablets construction, the materials to be prefabricated only requires little installation time.

- Earthquake resistant buildings as it absorbs earthquakes and moves along with this addition to transmitting loads from the roof to the foundation.

- Differences between panels, adapted to different types of constructions, various types of finishings.

gallery

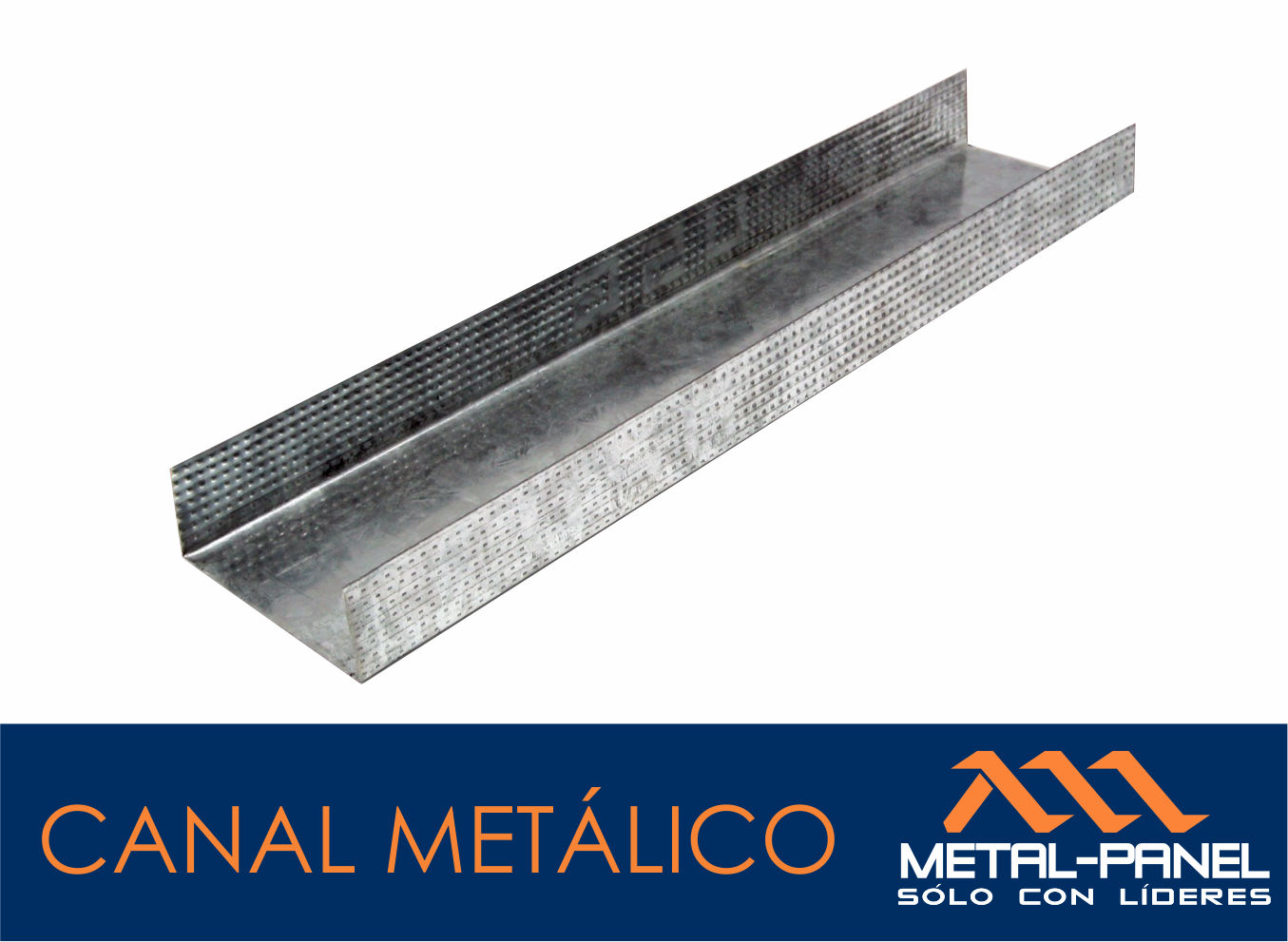

light metal structure

What is it?

The construction system has gained ground metal structures in society, Besides being lighter than traditional system, its construction is much faster and uses fewer labor. In this type of construction is used to the maximum space because no place is required columns in the middle of the space intended for the property depending on the design.

Light Metal Structures are a construction system widespread in our country, because they have a great capacity for employment resistant steel, This gives us the possibility of achieving comprehensive solutions, fast and aesthetic cover for large spaces. A being prefabricated parts and fixing means flexibility, delivery times are minimized significantly.

Our core materials for lightweight structures are channel pole and are mainly used for houses, walls, covered, perimeter skirts, partition walls, lattices and frame for facades.

If you already have a metal structure light we can cover it with an endless array of products that meet their needs as corrugated sheets and galvanized finishes pintros, Polycarbonate or Multypanel of Ternium brands, Metecno, Set y Makrolon.

Advantages and benefits

- high strength.

- Uniformity.

- Fast installation process.

- Thatching enclosures can be large gaps without many intermediate supports.

- Crosslinked stringers allow large cover areas.

- They are not altered with time.

- The high strength of steel per unit weight, It allows lightweight structures.

- The manufacturing and installation times are shorter than with any other material.

- Ability to work in crowded places or complicated access.

- Large growth potential, extension or modification as steel allows easily.

- The profiles are manufactured in modular steps that enable very precise settings.

- The sheets can be easily set with other profiles through rivets, screws or welding.

- The steel profiles are in different sizes and shapes to optimize their use.

- Steel structures have a cost recovery in the worst case as steel scrap.

- Steel is a material 100 % Recyclable besides being degradable "pollutes".

gallery

Tablaroca

What is it?

It is a construction material used for the execution of interior walls and ceilings and walls coatings. Often it used as plates, Industrialized panels or boards. It consists of a plasterboard between two layers of cardboard, so that its components are generally plaster and cellulose, advantage of good compression strength of the cast with good bending strength that gives the sandwich carton. The mounting structures typically made with galvanized steel profiles very low weight and thickness and width is standardized 1,20 meters.

Gypsum panels have a firewall core encapsulated in thick paper, generally recycled paper, natural finish on the front and a hard paper on the back, allowing maneuvering and easily cut, with cutter or knife, thus facilitating installation and immediate application of any coating or finish (painting, pasta, tile, etc.) joints (junctions between platens plasterboard) treated correctly during the installation process prevents cracking caused by movements of the racks.

Fire resistance

The plasterboard is nonflammable, that is to say, not fire even exposed to direct fire. It is made of hydrated calcium sulphate (CaSO4 + H2O) and other compounds. At the exposed to fire, calcium sulfate molecules loses water by evaporation, slowing the spread of the fire for several minutes. A dried or dehydrated the calcium sulfate disintegrates (craquela) and finally crumbles plate allowing passage of the heat to the other side of the partition.

Humidity resistance

There gypsum boards moisture resistant, They used in wet areas such as bathrooms, cleaning rooms, kitchens, etc., where it may be exposed to occasional splashes areas. Gypsum boards moisture resistant are made of treated paper which retards the absorption of water and fungal growth. further, the core plate contains special additives to avoid smearing or disintegrate. The plates are designed to withstand occasional water splashes, but they are not recommended to be exposed to rain or live or constant contact with water or steam as watering cans, showers or saunas.

It can be installed in bathrooms and kitchens home without any problems while you have an anti mold layer and must be removed and change. For decoration tile can stick to the same wall, but it must be done with a special adhesive system such as mortar glue specific for PYL.

gallery

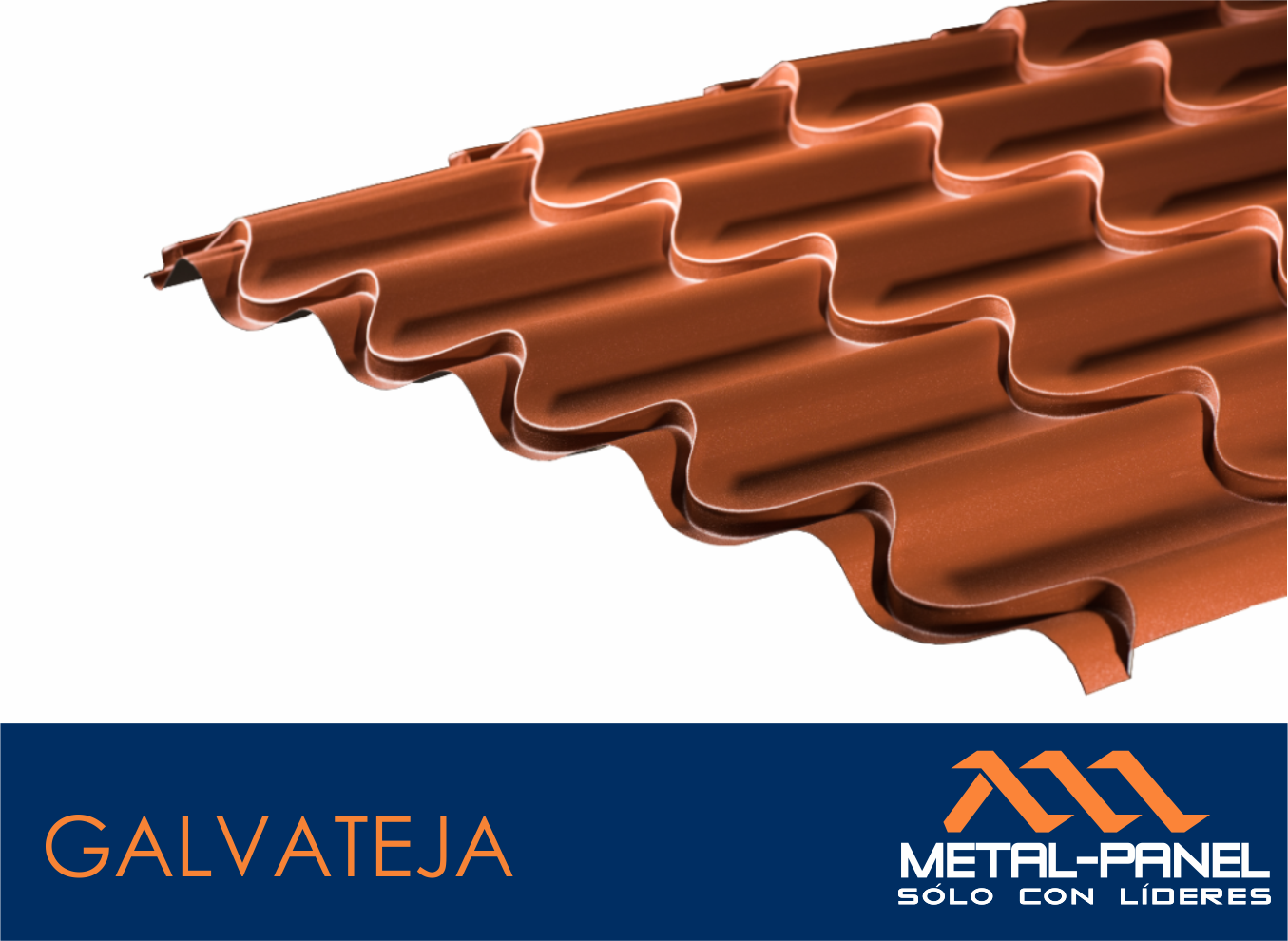

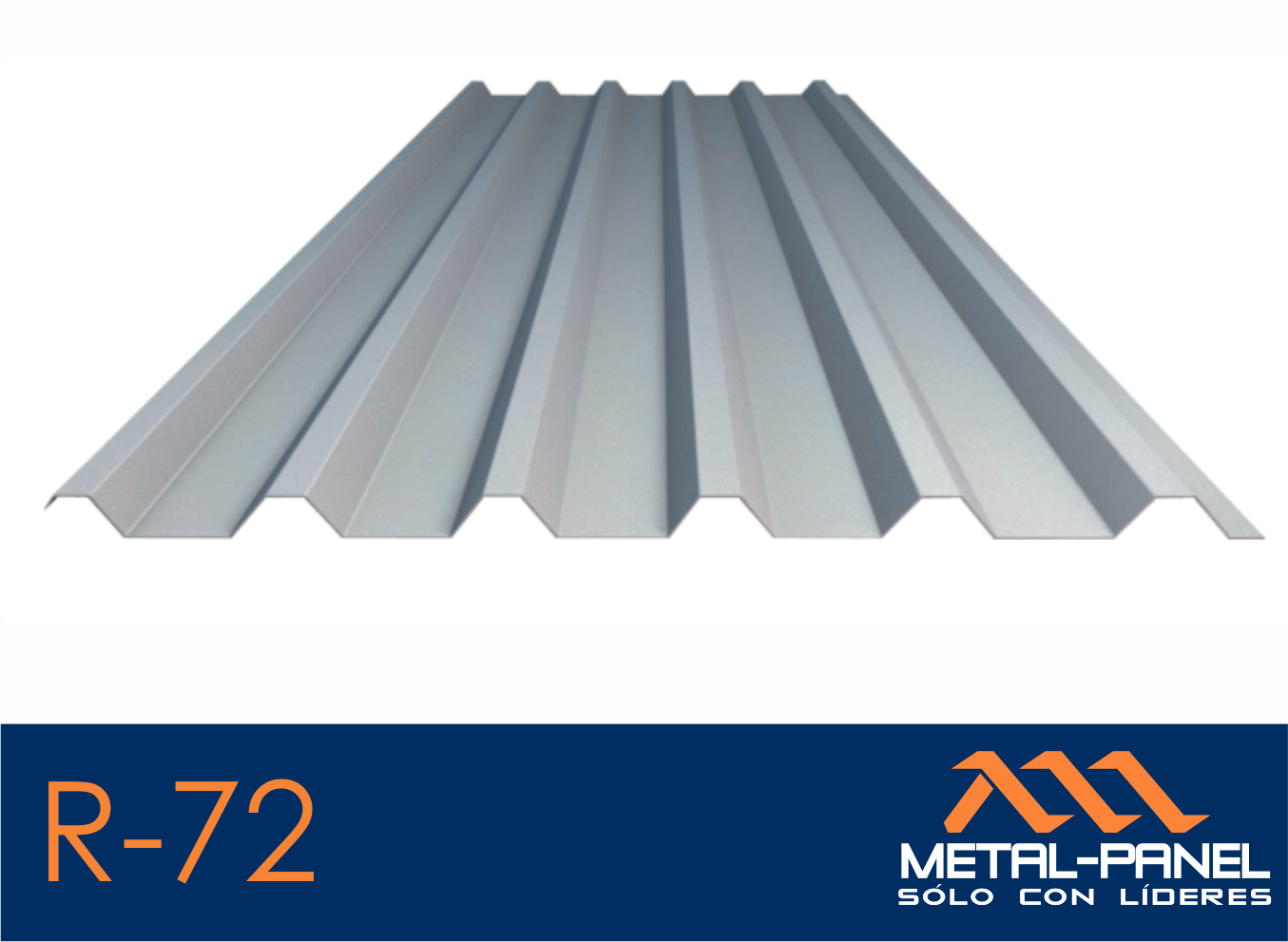

corrugated sheets

What is it?

The sheets are corrugated plates of different materials such as steel, the polycarbonate aluminum. They are used mainly in the construction industry for roofing or as surface coating, They can be used as sound or thermal insulation, as this type of sheet, by design, significantly reduces the number of elements as heat, Water, sound and even some chemicals. They are flexible and adaptable, plus they offer a great saving of resources in terms of cost and installation time.

Advantages and benefits

- Heat insulator

- UV-resistant

- Corrosion

- Design flexibility

- Fire resistance

- Chemical resistance

- weather resistance

- physical toughness

- minimal maintenance

- Covering power

- Environmental Protection

- Materials used in corrugated sheets

gallery

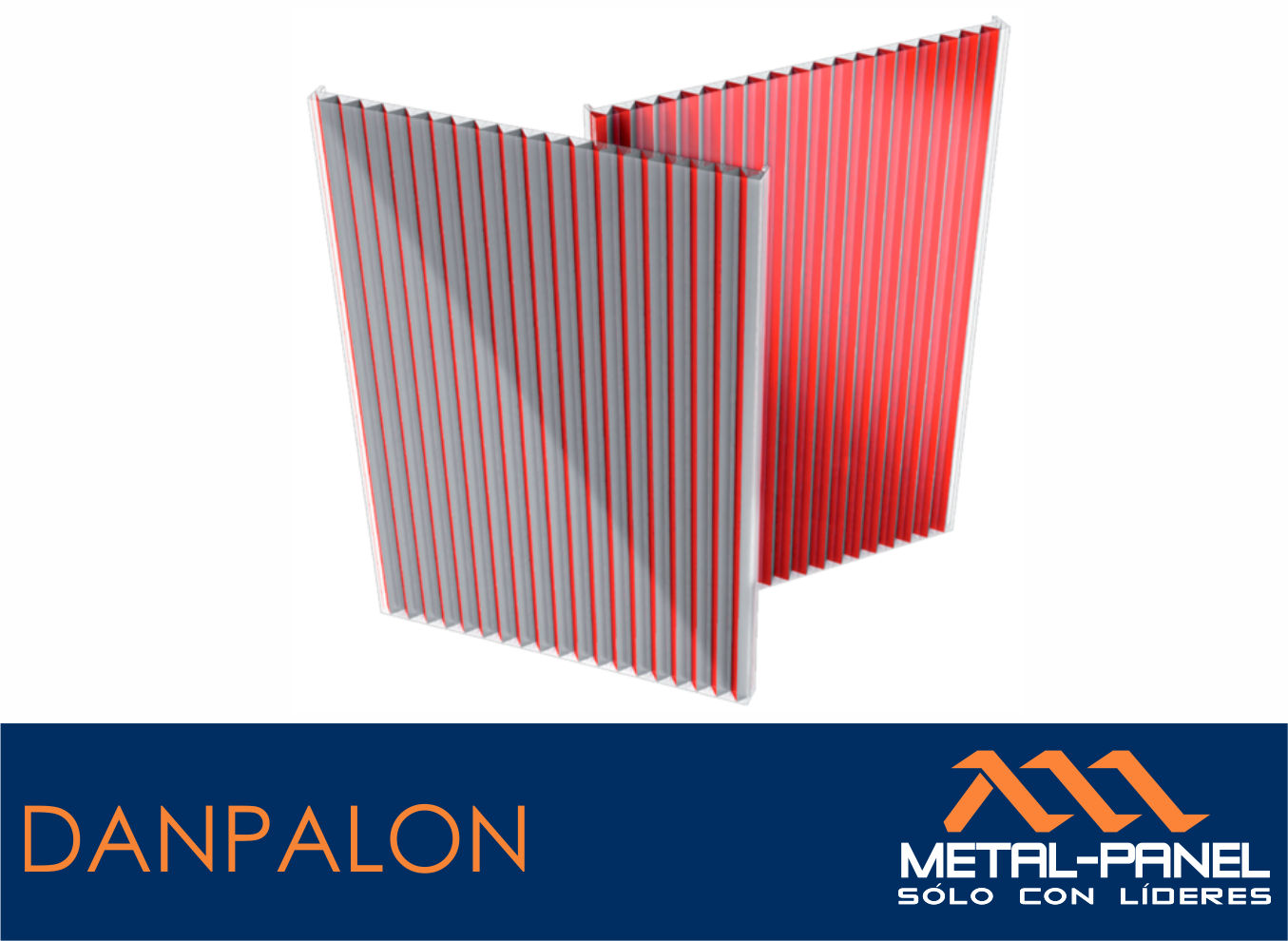

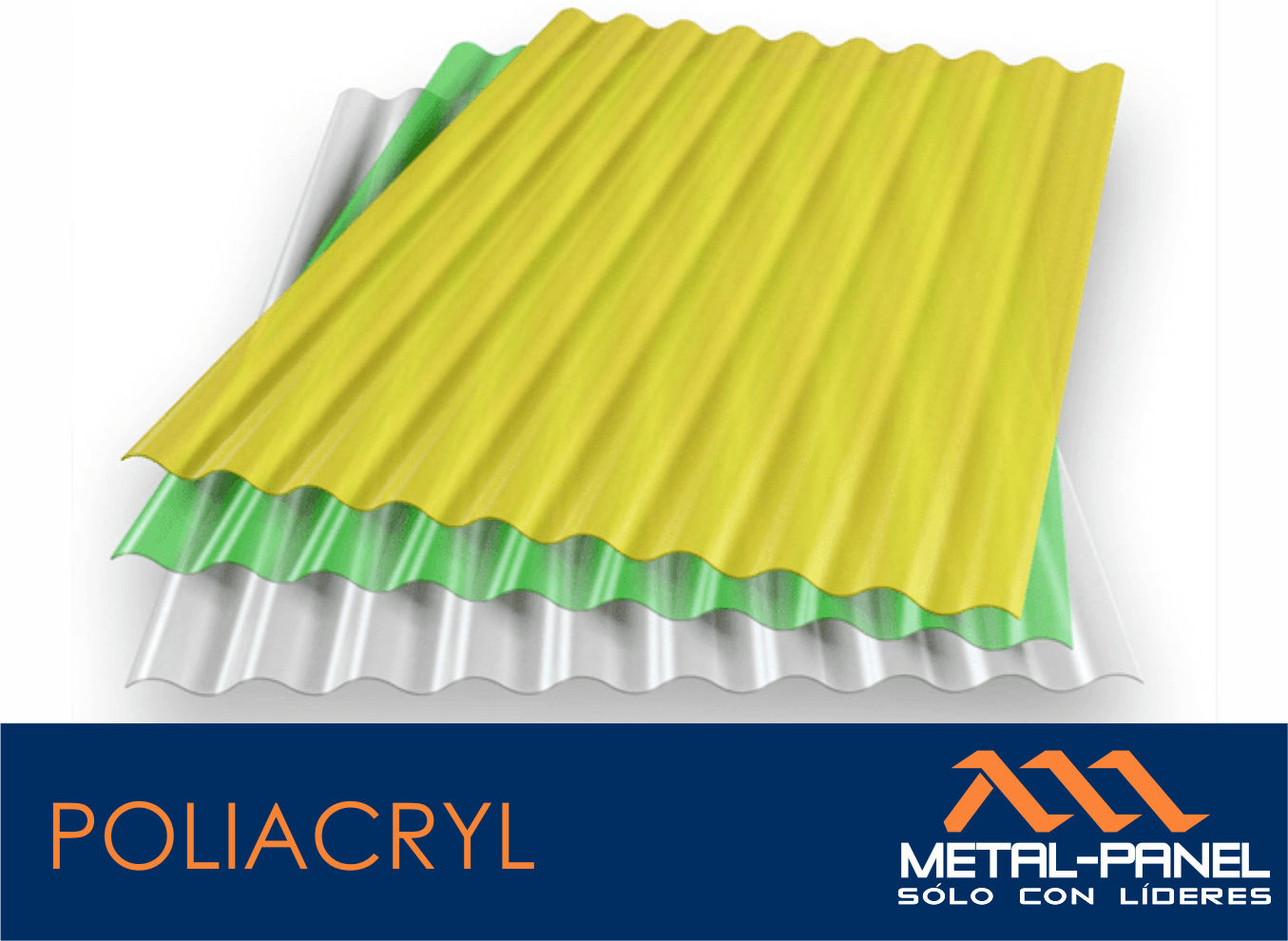

Acrylic and polycarbonate

What is it?

Polycarbonate is a thermoplastic with very interesting properties in terms of resistance to impact, heat resistance and optical transparency, such that the material has greatly penetrated the market in a variety of functions. Shaped sheet has three common presentations:

solid sheet - also called monolithic

sheet alveolar cell also known as

Corrugated sheet solid

It is a polymer formed of molecules of Bisphenol A, units with carbonate groups.

Impact resistance, which it is of the order of 200 times that of the glass, It is the property that allows to occur in alveolar plates, also known as "cell", with walls of reduced thickness and consequently with relatively low cost. In this presentation the material used in the construction of skylights and dome, having shifted largely acrylic.

Advantages and benefits

- The impact resistance extremely high.

- high transparency.

- High strength and stiffness.

- High resistance to thermal deformation.

- High dimensional stability, that is to say, high creep resistance.

- Good electrical insulation properties.

- High resistance to the elements, with UV protection.

Applications

Its high resistance to impact and optical properties have made this extraordinary thermoplastic earn an important position in the market for specific uses:

Transparent and translucent roofs, domes and skylights

This application is mostly used cell sheet for its lightness and reduced the cost of it emerges.

gallery